Iso 8 cleanroom particle specifications.

Iso class 8 clean room humidity.

Almost half of all clean rooms are based in china.

The concentration of particles that are 0 5 µm should be below 3 520 000.

Iso 6 cleanroom class 1 000 in theory for an entire room to reach iso 6 air cleanliness you need to enter the cleanroom via an iso 8 ante room then go through an iso 7 to finally get into the iso 6 as shown in the image.

The most common standards are iso 5 iso 8 class.

8 iest rp cc026 2 cleanroom operations 9 iest rp cc028 1 minienvironments 10 jis b 9926 clean room.

A sterile cleanroom for the pharmaceutical industry will need to achieve iso 5.

Iso 8 is the starting cleanroom level.

For iso class 8 particles smaller than 0 5 µm aren t considered.

Clean room classification iso class.

Now that you have a better understanding of cleanroom guidelines relating to humidity levels let s take a look at standards for cleanroom temperature.

As an example humidity is relative it s relative to the temperature it s at.

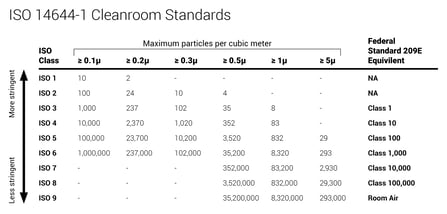

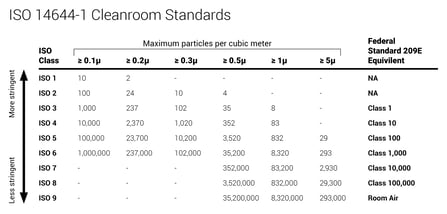

Clean room classifications are based on an eight class rating system with an iso class 1 cleanroom being rated the most particle free and iso class 8 allowing the most particles.

That translates again into the cost of construction and the cost of operating your clean room.

However class will greatly impact design considerations such as filtration hvac requirements and other design elements.

The class defines a minimum cleanliness level not a specific design.

This refers to the level of cleanroom particulate cleanliness based on a number of airborne particles of a certain size per cubic metre.

These plants generate various gases which can affect sensor elements facts figures about 23 of clean rooms are used for pharmaceutical and biotechnology.

In general the temperature of a cleanroom should be 21 degrees celsius or 69 8 degrees fahrenheit.

In reality however you can reach an iso 6 clean room with 1 recommendation is 2 airlock.

The particles range in size from 1 5 microns µm.

Iso 8 clean rooms do not require certain particle sizes to be tested either because concentration levels are too high or low to be tested but it cannot be zero.

Test methods for dust generation from moving mechanisms 11 semi e49 1104 reapproved 1211 guide for high purity and ultrahigh purity piping performance subassemblies and final assemblies 12.

Iso 14644 1 and older standard fs 209e determine class by the concentration levels of particles.

Usually a fluctuation of 2 degrees celsius is permissible.

Humidity sensor is very important.