When selecting the iron based soft magnetic powder from which to best manufacture powder cores for reactors pure iron powder and alloy powder were the candidates as shown in table 3.

Iron powder core saturation.

Our optimized alloys like oc and od are formulated specifically to deliver exceptional dc bias or core loss performance.

G18 55 385 6 6 green red a good dc saturation characteristics.

Pure iron powder has three advantages.

Iron powder cores series products sendust core mpp core high flux core 1.

Character of iron powder cores.

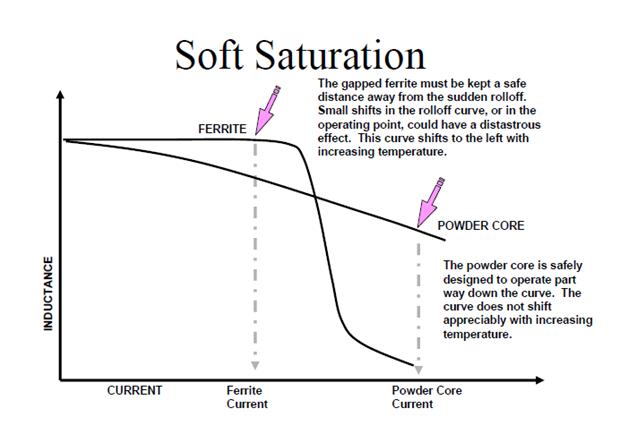

Furthermore the saturation flux density in ferrite cores is around 400 mt and decreases with temperature.

Iron powder cores have the saturation flux densities of more than 1t.

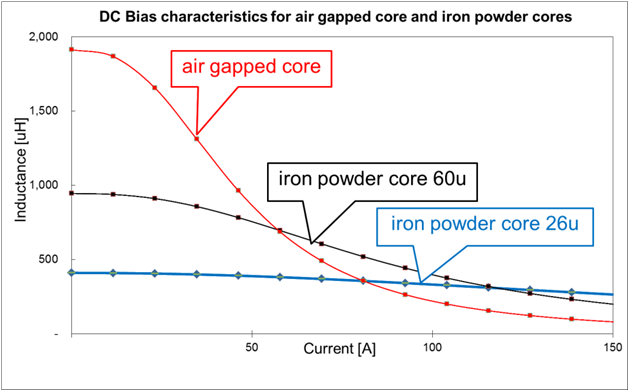

Iron powder cores do not need the additional air gap.

Saturation will decrease the permeability of the core causing it to have impaired performance or to become inoperative.

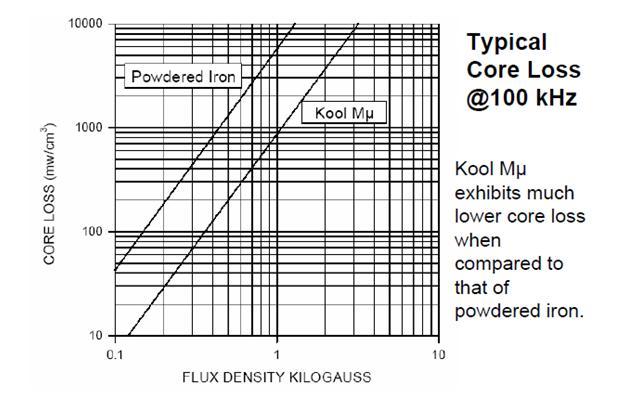

The characteristics of iron powder cores reduce the power loss.

Micrometals alloy powder cores are becomming increasingly popular for emerging applications in 5g hardware and power systems due to their high efficiency and reliability.

Powder core materials comparison.

The safe operating total flux density level for most ferrite materials is typically 2000 gauss while iron powder materials can tolerate up to 5000 gauss without significant saturation effects.

Iron powder cores are produced from very fine insulated particles of highly pure iron powder.

The magnetic properties of iron powder make it a good choice for many inductor applications but it is not a good choice for the main switching transformer.

In powder cores why is actual inductance different from calculated.

Dc bias for all powder core materials.

Magnetics powder core products kool mu sendust mpp molypermalloy kool mµ max kool mu hƒ edge tm high flux xflux and 75 series materials are distributed air gap cores that are primarily used in power inductor applications specifically in switched mode power supply smps output filters also known as dc inductors.

Powder core solutions for next gen communications.

Ppm oc material density g cm3 color note y8 35 255 6 5 yellow red a good high frequency material it has low core loss and good linearity under high bias conditions.

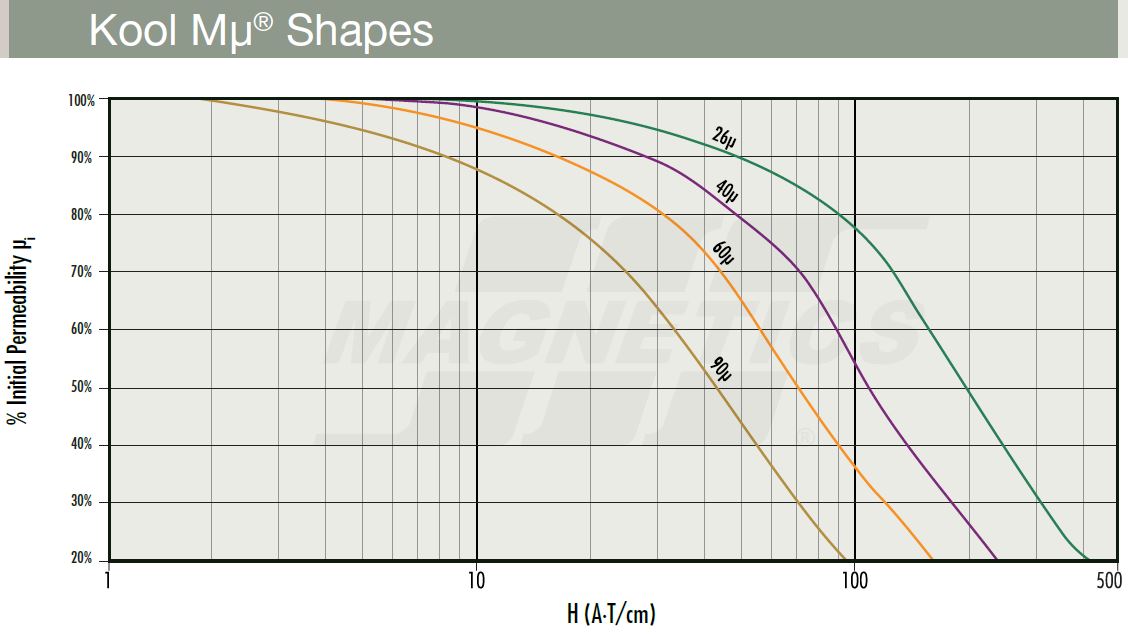

Figure 3 plots permeability vs.

Iron powder cores general material properties material reference permeability µo temp.

This prepared powder is compressed under extremely high pressures to produce a solid looking core.

For more information on how the materials compare view our powder core materials presentation.

High saturated magnetic induction strength it may work in large current without saturation.

The saturation characteristic shown by powder cores varies by only a couple of percent even across quite wide temperature ranges.

I high saturation magnetic flux density that is suited to reducing the size of compo.

Magnetics measures inductance in a kelsall permeameter cup.